Forklift Safety Tips

08 August 2022

Forklift Safety Tips

Many workplaces in Australia use forklifts to lift, stack, and transfer loads. However, they continue to cause workplace deaths and injuries yearly, resulting in high financial and human costs for workers, industry, and the community.

Why is forklift safety important?

Forklift safety refers to the procedures used for proper forklift operation, including before and after forklift operations. Forklift safety is critical for all businesses to protect their employees' welfare and safety. There are numerous causes of forklift accidents, with pedestrians being the most common. Forklift rollovers continue to be the leading cause of serious injury and death.

Top 10 Tips Forklift Health and Safety

These Forklift safety tips will reduce the risk of incidents while protecting the operator and those nearby.

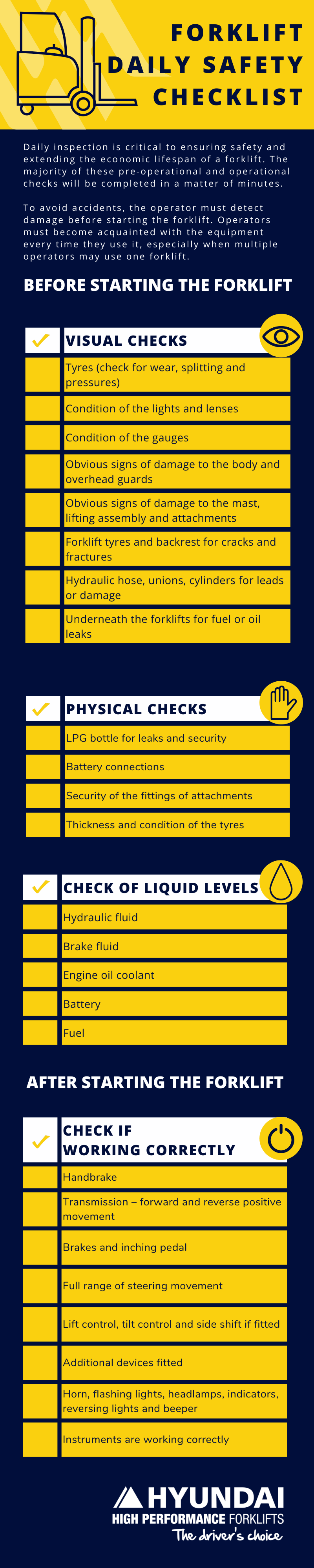

- Always perform a daily safety checkA forklift operator is required by law to conduct a safety check on each forklift that he operates for the first time each day or shift. The employer must record and retain that safety check in an audit or incident. Some safety checks, such as lights, seat belts, and chains, are performed post-operatively, that is, while the forklift is not in use. Others, such as brakes and hydraulics, are completed while the forklift is in operation. Each company will have different policies in this regard, but each forklift must have at least one safety check per shift. Use our helpful checklist above if you need one.

- Forklift operator safety responsibilitiesForklift operators should attend regular refresher training courses with their employer and a licenced training authority to stay current on changes in legislation, safety measures and remain properly trained for the job.

- Follow employer-specific safety measures.Forklift operators should comply with all legislation and any safety measures imposed by their employer. Ensure that your employees and visitors, including delivery drivers, follow your traffic management plan and site safety rules.

- Report risksWhen workers identify risks in their workplace, they should report this immediately and work with employers to reduce or eliminate the risk involved.

- Wear the correct clothingForklift operators should wear appropriate safety gear, such as safety shoes, hard hats, and a high-visibility jacket. Keep loose clothing tucked away to avoid getting caught on the forklift.

- Ensure rating information is visibleEnsure rating information is in a visually accessible location for operators to be aware of the limitations of forklifts. As each type of forklift has its structure, weight limit, travelling speed, turning radius, and usage, knowing your equipment is essential for adhering to the best safety practices.

- Drive at the appropriate speedDrive your forklift within the speed limits specified. When making sharp turns, it is critical not to stop, turn, change directions, or move quickly, as these actions can cause the forklift to tip over. If your forklift begins to dip, do not attempt to jump clear of it. Experts advise staying in your vehicle, gripping the steering wheel, and bracing your feet.

- Always fasten your seatbeltWhen operating a forklift, always wear your seatbelt and keep both hands on the steering wheel at all times. This will help you maintain control of the truck.

- Ensure loads are stable and balancedCheck loads for balance before placing them on the loading dock. To increase the stability of the equipment, travel with the load tilted backwards and the forks as low as possible, especially when navigating on ramps. If necessary, use ropes or bindings to secure stacks and heavy loads and ensure that any pallets or skids used are the appropriate weight for the load.

- Separate people from ForkliftsUse barriers or guardrails to keep people as far away from moving forklifts as possible.

- Mark safe work zonesIf you cannot physically separate forklifts from people, clearly mark walkways and safe work zones, and make sure your workers stick to them.

Following these tips can help reduce the chances of forklift accidents, but human errors will occur regardless of safety precautions. That is why investing in a forklift with superior safety features can help bring peace of mind to drivers and business owners..

Hyundai Forklift Safety Features

At Hyundai High Performance Forklifts we future-proof your business with Hyundai smart technology and safety features. Our cutting-edge technology-driven features address the common causes of forklift accidents. Our features proactively reduce the number of dangerous situations in your workplace, reducing injuries and improving operations by automatically identifying and responding to potential risk, correcting user error, and providing operator alerts.We offer the latest technology as standard, so what other brands offer as add-ons we've built into every model! Watch our managing director Jeff Akres explain the safety features packed into Hyundai High Performance Forklifts.

Forklift Daily Checklist

Hyundai Forklifts Australian Forklift Champion crowned

Forklifts are a significant investment and purchasing one or hiring one via a lease can have huge consequences for your business. So what’s the best option? We’ve broken down the benefits and disadvantages of both options so you can make an informed decision, no matter which company you decide to purchase from.